Sand washing and other sand recycling methods

Sand is a finite resource that has become more expensive due to taxes. It is often worthwhile to recycle sand directly on site rather than landfill and truck in new sand.

Depending on the content of the sand, there are different methods to ensure recycling and to transform the waste into a useful product.

Filter sand is a good example where it is possible to avoid removing materials and instead recycle the contaminated sand into new filter sand directly on site.

Recycling of filter sand

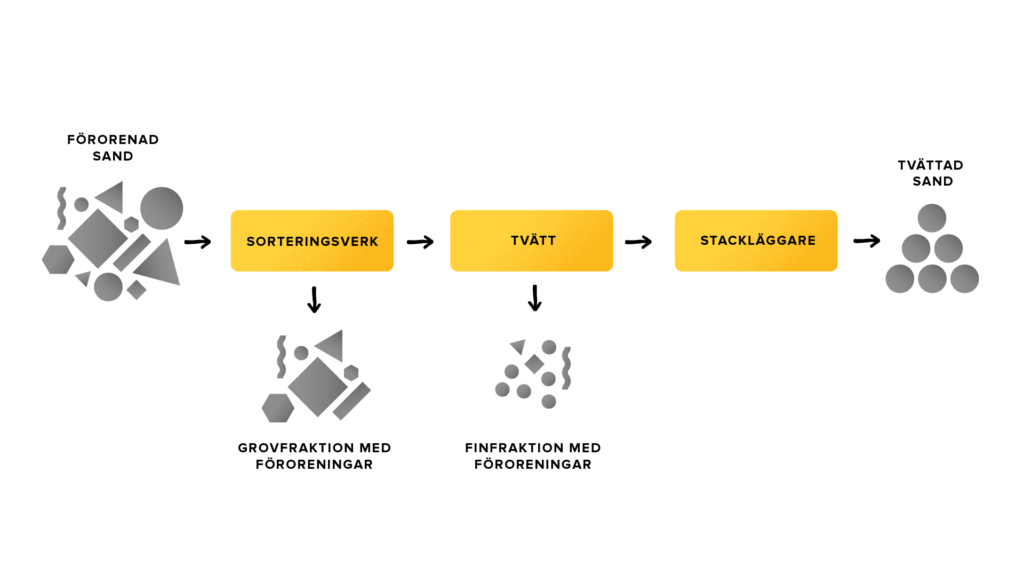

Filter sand is used, for example, by water treatment plants and heating plants. Filter sand can be recycled using Screening plants and washing. By washing the sand, it settles and fine particles with contaminants such as algae form one fraction while clean sand forms another fraction that can be reused with full capacity.

The recycling of sand is particularly relevant when it comes to filter sand because filter sand needs to have certain properties to function optimally as a filter. A special sand is used as filter sand and its availability is limited in Sweden. Therefore, it can lead to longer transports and thus greater impact on the environment and costs.

Recycling the sand avoids long transportation and the cost of buying new sand. It also means reduced landfill costs and major environmental benefits in terms of reduced traffic and reuse of existing materials.

Why should you recycle sand?

Sand is a finite resource that nature does not produce anew. Landfilling sand is often a worse option than recycling it on site as it involves high costs for transportation, landfill fees and the purchase of new sand.

Sand is one of the most widely used materials in the construction industry as it is a common component of mixtures such as cement and concrete. As homes, commercial premises, roads and other infrastructure are built, more and more sand is extracted. The use of sand in everything from concrete to building foundations and glass manufacturing means that the supply is decreasing, pushing up prices on the world market. Recycling sand has therefore become more relevant.

Since there is now also a tax on natural gravel, the calculation is more favorable for recycling the sand. We have several different methods for sand washing.

What materials do you have?

Let us propose the best solution for you. We can also come out to test-drive your material.

Recycling of waste sand

Every winter, large amounts of grit are used on our roads. When collected, it often contains contaminants in the form of sticks, plastics, etc.

The same method that Norditek uses to separate plastics from compost soil can also be used for waste sand. This means that the waste sand can be reused again next winter instead of going to landfill. This provides both a better economy and is better for the environment.

Washing equipment for sand

Sand can be recycled from excavated material, which also contributes to better resource management. We have several different washing facilities and methods to optimize the recycling and handling of excavated material and sand. We are more than happy to help you find the right machine or concept depending on your local conditions.