Significant benefits of recycling excavated material

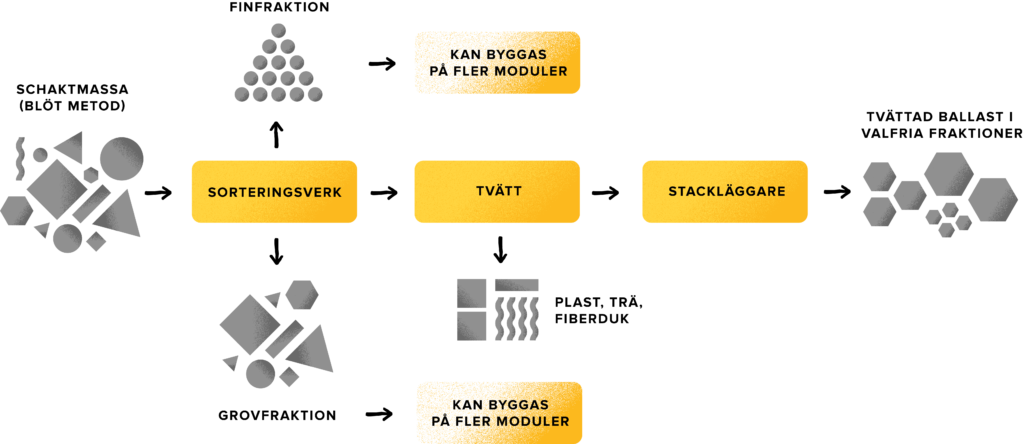

There are now well-developed methods for obtaining the required products. Depending on the content, the right method is used to ensure recycling and transform a waste or filler material into marketable products and/or fractions.

The main benefits of recycling excavated soil are:

- Thousands of journeys of heavy traffic in inner cities can be avoided to remove materials that can be reused on site.

- By recycling materials, there is no need to mine new rock or excavate new soil and transport heavy traffic to the site.

- Major economic benefits for landowners in reduced transportation, reduced purchasing and reduced landfill costs.

- Huge environmental benefits in terms of traffic reduction and reuse of existing materials.

Sometimes excavated material is used to fill in/level the ground, or to lay foundations for buildings. This is usually an emergency solution that is less profitable for the wallet and the environment.

Figure 1. Norditek's electrically powered coarse sorter that sorts excavated material into three fractions with high capacity and quality.

Analyze the excavated material first

An important part of the work involves analyzing the content of the excavated material in order to make the right choice of recycling method. If they are contaminated, it is often possible to enrich the contamination so that only a small part needs to be landfilled or destroyed.

The analysis is simply important to determine what can be recovered and what requires other measures. Some contaminants can cause damage and pollution in the area.

By conducting the analysis in a timely manner, it is possible to plan the most cost-effective and environmentally friendly actions with the material.

What is aggregate?

Excavated soil is a residual material resulting from an excavation, such as road construction, building construction or other infrastructure projects. Excavated soil simply contains what was once placed there before it was excavated.

When reusing excavated soil, there must be a specific purpose or objective for its use. Excavated soil should be used as a substitute for another natural material.

Figure 2: A concept where a coarse screen removes rock, a star screen removes clay and fine fraction and windshifter removes contaminated organic material.

Movie 1: Shows a star sieve that transforms excavated material into high quality soil.

Handling of excavated soil

Today, millions of tons of excavated material from road construction, industrial establishments, soil remediation, and other infrastructure projects are transported. The arguments below are common reasons why excavated material is transported.

- Loose masses without bearing capacity - Possible solution could be to stabilize loose masses with bentonite or lime in a high capacity Screening plants .

- Mixed soils with high moisture content - Possible solution is to sort by size with star sieves, allowing topsoil to be reused on site or sold.

- Contaminated soils - Possible solution is to sort out the fine fraction that often contains contaminants and blow out organic matter that often absorbs contaminants.

- Stone too large to be used as soil - Possible solution is to divide the stone into several fractions such as macadam, bedding, sand, etc. These fractions can then be used to replace virgin material.

If you want to know how much you can save money and reduce your environmental debt, don't hesitate to contact us to calculate excavation masses and get solutions for your specific project.

Recycling of excavated material reduces landfilling

Effective recycling of excavated soil can contribute to better resource management. There are currently rules that determine whether or not excavated material should be regarded as waste. Rubble that is not considered waste is recycled through the general environmental requirements of the Environmental Code, while rubble that is considered waste must be examined by an authority.

There is also the option of transporting the mass to a more advanced treatment facility, where analyses are carried out to maximize recovery and detoxification. The material that cannot be recycled or detoxified finally ends up in a controlled landfill. Norditek's experience is that with the right methods and machinery, it is possible to further reduce landfill.

Price of excavated material

The cost of removing excavated soil varies greatly. It depends on what the mass contains, the size of the volume, where in the country you live and how far you are from the nearest treatment facility.

In some places, excavated material is only used as backfill, which is often a huge waste of resources. There are also operators who landfill excavated soil even though a large part of it can be recycled. This is often based on ignorance and leads to a huge waste of resources in terms of money, carbon dioxide, emissions and increased production of raw materials.

Film 2: Shows excavated masses becoming new topsoil through a finger sieve.

Film 3: Shows the washing of excavated material.

Film 4: Shows sticky masses that are stabilized by adding lime in the screening process.

Movie 5: Shows soil sorting with flip flow technology.

Sorting shaft masses with Norditek

Handling of excavated material is a common problem today. Today, millions of tons of excavated material from road construction, industrial establishments, soil remediation and other infrastructure projects are transported. In many cases, materials are excavated many miles away because someone wants to get rid of the excavated material, to be deposited or used as fill material.

Recycling of excavated soil saves the environment and reduces costs. Even if the masses contain environmentally harmful substances, it is often possible to recycle large parts of the excavation mass such as stone, soil, wood, gravel, metal and thus reduce the use of virgin products, which is a positive environmental aspect.

We have well-developed methods to optimize the recycling of excavated material. We have machines developed to handle excavated material and topsoil. We are more than happy to help you find the right machine or concept depending on your local conditions.

What materials do you have?

Let us propose the best solution for you. We can also come out to test-drive your material.