Screening plants

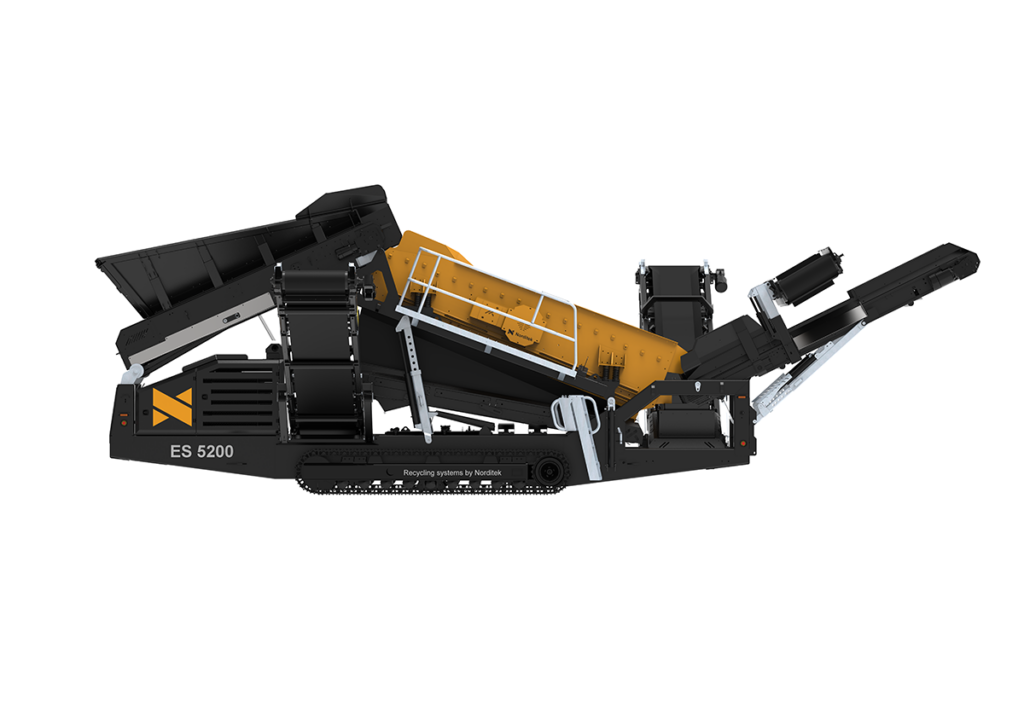

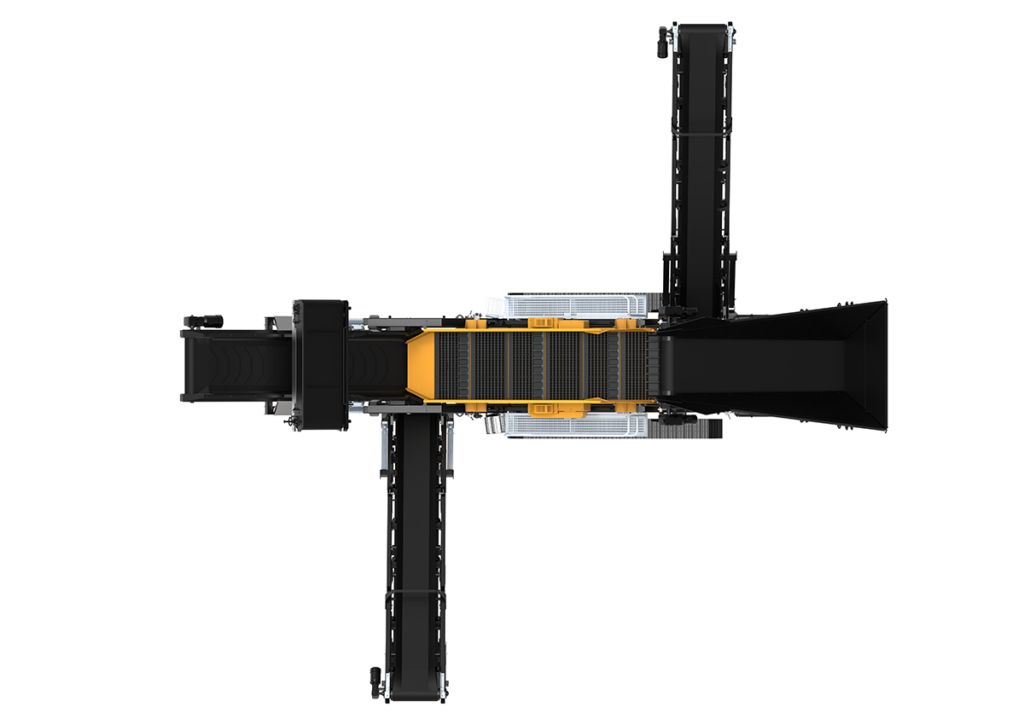

Norditek ES5200

Det nya, eldrivna sorteringsverket ES5200 ökar återvinningsgraden på komplexa material och avfall samtidigt som det sänker förbrukningen av el. Sorteringsverket är utvecklat för att köra både avfallslåda (flip flow-teknik) eller berglåda. Sikten fungerar optimalt ihop med Norditeks andra maskiner.

For fractions 0-1000 mm

For waste and masses

Fits Norditek's modular system

Product description

ES5200 har en utökad siktyta som ger renare fraktioner. Flip flow-tekniken möjliggör en ännu effektivare återvinning av avfall och massor. Sorteringsverket kan även köras med berglåda. Det är designat med energieffektivitet i åtanke, vilket leder till betydande besparingar i driftskostnader. Den lägre ljudnivån ger också en bättre arbetsmiljö.

Sorteringsverket har ett integrerat genset och är designat med en smart sekvensstart som kan driva fler moduler samtidigt. Den avancerade styrtekniken ger operatörerna bättre kontroll och ökad precision i produktionen. Föraren kan köra maskinen med en avancerad fjärrkontroll för att förenkla och effektivisera drift och övervakning.

It is possible to upgrade the machine with a tracking system and get production data for all fractions. The machine is equipped with overband magnet and end-roller magnets in the factory, which guarantees high performance and efficiency.

Technical specification

- Power: 55 kW

- Electricity: 400V/125A

- Föreslaget elverk: Inbyggt genset

- Maximum capacity: Varies

- Feed height: 3660mm

- Attachment for migration: Caterpillar

- Connection glove: 125A

- Feed conveyor & feeder: 1300mm conveyor (or lamella feeder)

- Matarficka: Från 7 m3

- Engine: Perkins Stage 3 (available with Doosan Stage 5)

- Viewing area: 5000mm x 1400mm

- Adjustable angle of sight box: Yes

- Upper deck: Waste box or salvage box

- Stepped tires with twist fingers: Yes

- Subdeck: Waste box or rock box (flipflow or steel mesh)

- Assembly line: 1200mm

- Fine fraction band: 900mm

- Intermediate fraction belt: 900mm, carrier belt

- Overhead conveyor belt: 1200mm, carrier belt

- Genset: Diesel-elektrisk 65kva (inbyggd)

- Uttag: 32 amp för vidarematning till extern förbrukare

- Automation & Control: Touch screen HMI, Autostart sequential start and stop

- Weight: 32 tons

- Working dimensions: Width: 14.0 m, Length: 14.6 m, Height: 3.2 m

- Transportmått: Bredd: 3.0 m, Längd: 16.5 m, Höjd: 3.4 m

- Options

- Engine: Doosan Stage 5 (No AdBlue)

- Radio Control: Wireless Remote Control

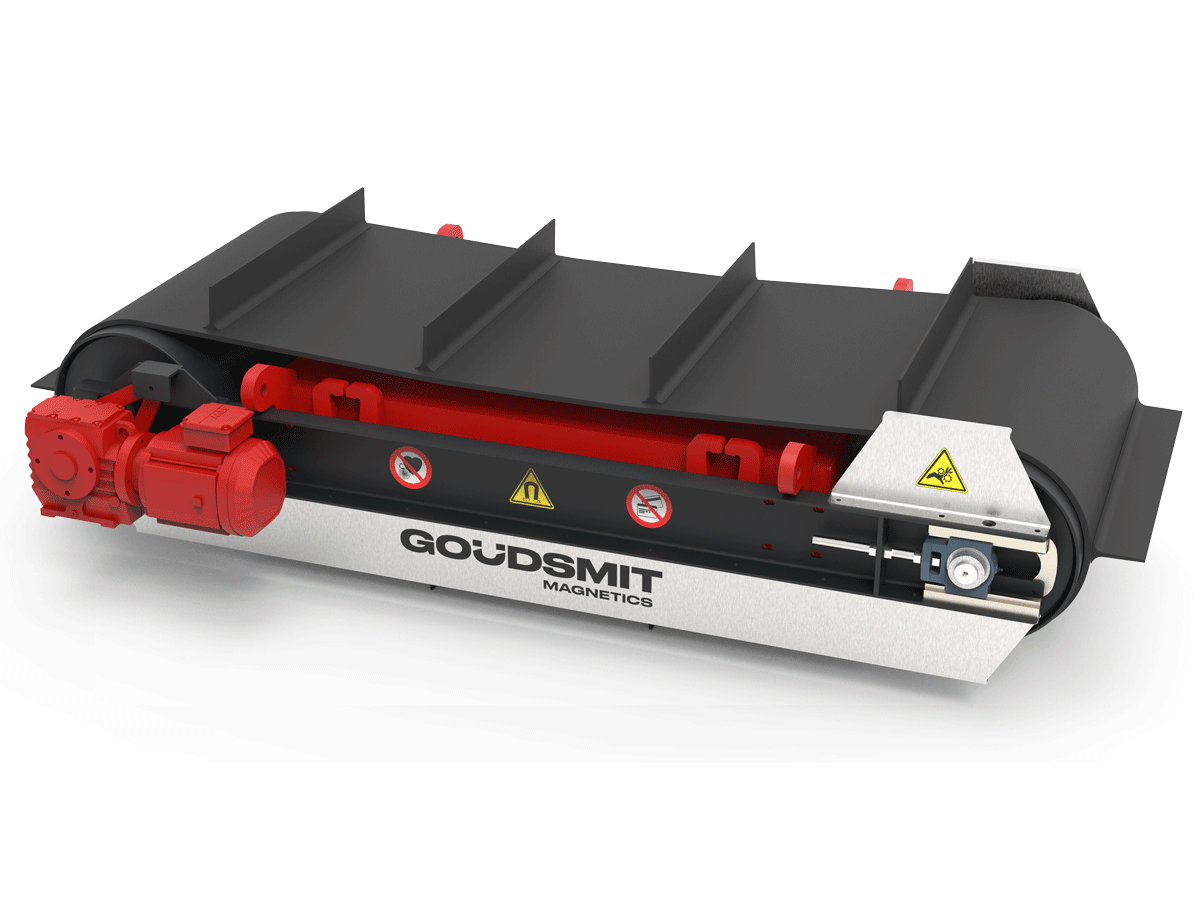

- Magnet:

- Overband magnet on overfraction belt

- End roll magnet on fine fraction belt

- End-of-roll magnet on intermediate belt

- Feeder: Lamella feeder

- PAS: Positive Air Pressure System for Control Panel

Product sheet

Feel free to contact us if you have any questions about our products and services.

Film

Overband magnet

Magnets

PU cloths on the deck

Steel sheets

Stainless steel sheets

Accessories

Type E: Flattop mask

Steel grid