The material

Recycling of concrete

Today there are great opportunities to recycle more of the concrete that previously went to landfill. With our concrete recycling solutions, it is possible to process more concrete waste and to carry out shorter projects in the field, saving significant costs for transportation, landfill and environmental fees.

Why recycle concrete?

Recycled concrete offers great cost savings and the technology for recycling concrete has developed greatly. Norditek is currently working in several areas to create new products from concrete waste. Norditek has ready-made concepts to test on your waste directly.

Our technology to recycle concrete

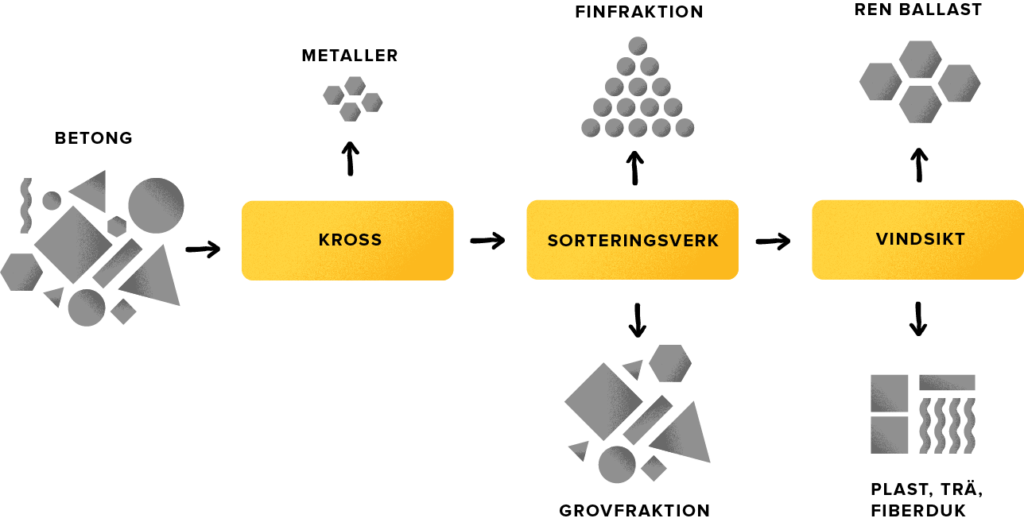

With Norditek's mobile concrete recycling plants, it is possible to process more of the material. Depending on the characteristics of the waste, crushing, screening, wind screening, magnets (in some cases eddy current magnet) and water bath are used to recover the maximum amount of the material.

The flexibility of our concrete recycling plants is very high thanks to the mobility of the machines, which can be moved around for shorter projects and to optimize production.

Machines for this concept

What can concrete waste be used for?

Concrete waste can, for example, come from houses to be demolished, or waste from the concrete industry. Residual materials from industrial processes can now be recycled as aggregates or as additives in new concrete. Residual concrete or demolished concrete can be crushed and recycled as aggregate in new concrete, as filler or, thanks to new technology, as an additive in new concrete.

A new technical solution by Norditek makes it possible to reuse the fine fraction from the recycling of concrete to replace virgin cement. This has not previously been possible, but through developed material handling it can now be a cost-effective alternative to new cement production.

Recycling of construction waste

Construction and demolition waste often contains large amounts of concrete. This waste makes up a significant proportion of all waste sent to landfill in Sweden. However, because it is a natural material based on rock and stone, concrete can be 100% recycled. By recycling the material, it can replace the extraction of virgin rock material.

Concrete is a common material in construction waste. As a rule, concrete waste consists of more metal than asphalt, because it contains reinforcement. This metal is valuable and can be easily recycled with the right technology. The metal recovered from recycling can be melted down and turned into new raw materials and products. This process allows us to obtain very pure metal with retained properties.

Framtiden för betong

At present, concrete is mainly recycled by crushing it and using it for things like soil and road filling. In order to develop the recycling of concrete, new EU standards have been introduced which allow concrete to be produced using crushed concrete as aggregate under certain requirements and conditions.

As there are significant environmental benefits to recycling concrete, it is important that we continue to explore and develop the technology. Instead of using natural gravel or crushed rock as aggregate in concrete, we can reuse concrete waste as aggregate in new concrete, thus having less impact on the ecosystem. This is especially true for the new technology that enables the recycling of the fine fraction for new concrete production.

Dry ballast problem solved

Den ballast som återvinns från betongavfall är ofta för torr för att ge en tillräckligt god kvalitet i återförandet till nya produkter. Genom att mätta ballasten med vatten får den rätt egenskaper vilket är möjligt genom att vattenmätta den i ett vattenbad från Norditek. Det är ett steg framåt och fler pågår när vi tar återvinningen in i framtiden.