Recycling of bark landfills

Our The bark sorting solution removes gravel and stones from urban bark and old bark dumps. This improves the quality of the biofuel, which in turn means that the biofuel can be sold at a higher price.

A similar solution is also successfully used to improve the quality of recycled wood. This is done by reducing the fines in the final product using a 5 mm sorting deck on a Backer star screen together with a windshifter that can remove impurities of different density, such as plastics, aluminum, etc.

However, for the recycling of bark and urban bark, it is only a matter of separating the inert material.

Biofuel from bark and anvil bark

Bark is generated when sawlogs or pulpwood are debarked, when the bark is removed from the log. Bark is used almost exclusively for burning.

Cleaning bark is instead a by-product that arises in places where mainly timber and pulpwood are stored. The bark released from the wood is swept into piles which will therefore contain sand, gravel and stones.

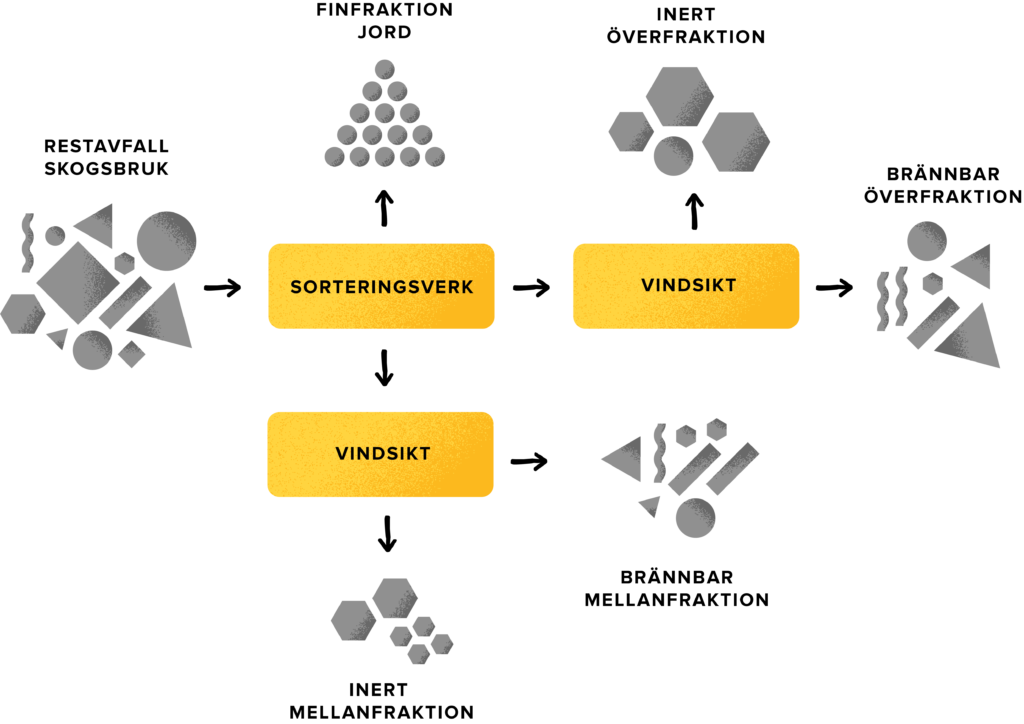

In order to obtain high quality biofuel, the inert material needs to be separated, which can be done with the help of a star sieve and two wind sieves which then give a fine fraction of soil, as well as upper and intermediate fractions of inert and combustible.

Higher energy value with star sights and windshifter

The star sieve is essential to achieve the high energy value of this fuel and depending on the nature of the input material, one or two wind sieves are used.

In the case of forest waste with a lot of stumps, the material first needs to go through a crusher where it is crushed together with other larger pieces of wood before it can be sieved from smaller material.

Backer's star sieves have a separation limit down to 5 mm, which is unique for star sieves. Backer's 5 mm rubber stars have a large diameter which increases the lifespan and ensures that the material is properly screened.

windshifter is a technique used to remove light materials, such as the wood, from the heavy waste. It works by creating an air stream that blows away the light particles while retaining the heavier waste. This is particularly important as it reduces the ash content of the recycled material, which is crucial for increasing its energy value.

Benefits of biofuels

- Biofuel has no negative impact in terms of CO2 emissions as it is climate neutral.

- Biofuels are renewable energy because they are made from natural and renewable raw materials.

- Biofuel is a more cost-effective choice as savings can amount to around 60-70% of previous costs.

Using biofuels derived from bark and biomass is both environmentally friendly and good for the climate - as long as you use high quality biofuels produced in a controlled and sustainable way.

Energy recovery from bark

Norditek's quality-enhancing concept for sorting and producing biofuel includes Backer's star screen and two Norditek VS1220 wind screens. Backer's star screens have a separation limit down to 5 mm, which is unique for star screens. Backer's 5 mm rubber stars have a large diameter, which increases the service life and ensures that the material is properly screened.

This ensures efficient energy recovery from forestry residual waste. When waste cannot be reused or recycled, energy recovery becomes an option to harness the energy from residual waste.

What materials do you have?

Let us propose the best solution for you. We can also come out to test-drive your material.