Recycling of stumps and GROT

Forest waste, including stumps, branches and bark, is a natural by-product of forestry and the wood industry. Historically, this waste was often burned or dumped in landfills.

But with increasing awareness of environmental issues and the need to reduce landfill, Norditek and similar companies have taken initiatives to utilize this potentially valuable material.

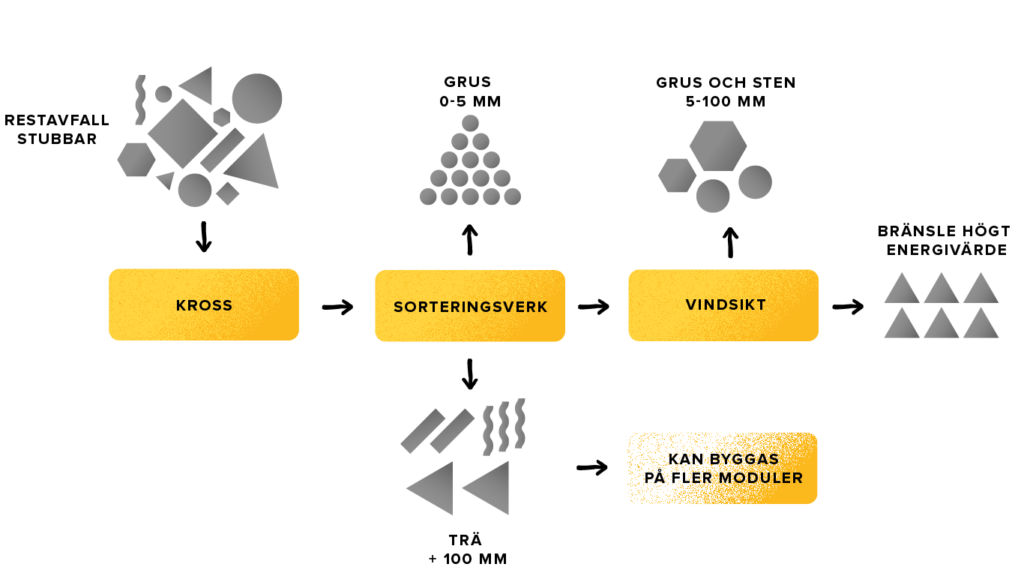

Our stumps plant: Crusher, Star Sifter and windshifter

Norditek uses a combination of three machines to efficiently recycle forestry waste with stumps: crushing, star screening and windshifter.

1. crushing

Crushing is the first step in the process where forest waste is broken down into smaller pieces. This makes the material more manageable and prepares it for the next steps in the recycling process.

2. star sifter

The star sieve is used to separate materials of different sizes. In the case of forestry waste, this means that stumps and other larger pieces of wood can be screened from smaller materials such as branches and leaves.

Backer's star sieves have a separation limit down to 5 mm, which is unique for star sieves. Backer's 5 mm rubber stars have a large diameter which increases the lifespan and ensures that the material is properly screened.

3. windshifter

windshifter is a technique used to remove light materials, such as the wood, from the heavy waste. It works by creating an air stream that blows away the light particles while retaining the heavier waste. This is particularly important as it reduces the ash content of the recycled material, which is crucial for increasing its energy value.

For the recovery of bark, star sieves are used and windshifter

Norditek's star screen and windshifter plant converts forest waste with bark from low energy value and high ash content to low ash content and high energy value.

The end result is the same as for the stubble plant where about 70% of the input material comes out as finished fuel free of stones and gravel, in the right size for a bio-boiler (5-100 mm).

Results: High energy value and low ash content

Norditek's crushing, screening and windshifter plant makes it possible to obtain a high energy value fuel. Here are some of the key results:

High energy value

By effectively separating and treating forest waste, Norditek can convert it into fuel with high energy value. This is particularly valuable at a time when demand for renewable energy is high and forest waste can be used as a resource to produce heat or electricity.

Low ash content

One of the major benefits of Norditek's technology is the ability to reduce the ash content of the recycled material. Low ash content is crucial because high ash content can cause problems in the combustion process and lead to pollution of emissions. By reducing the ash content, Norditek makes forest waste more useful and environmentally friendly as a fuel.

The right size and quality for a bio-boiler

Norditek's crushing, screening and windshifter plant demonstrates how efficient recycling can turn waste into a valuable resource. By transforming forest waste from low energy value and high ash content to low ash content and high energy value, Norditek contributes to reducing the load on landfills and promoting sustainable use of forest resources.

About 70 percent of the input material comes out as finished fuel free of stones and gravel, in the right size for a bio-boiler(5-100 mm).