Major benefits of recycling bearings directly on site

The main advantages of recycling directly on site are:

- Thousands of journeys of heavy traffic in inner cities can be avoided to remove materials that can be reused on site.

- By recycling materials, there is no need to mine new rock or excavate new soil and transport heavy traffic to the site.

- Major economic benefits for landowners in reduced transportation, reduced purchasing and reduced landfill costs.

Machines for this concept

Handling of subsoil and excavated materials

Today, millions of tons of excavated material from road construction, industrial establishments, soil remediation, and other infrastructure projects are transported. The arguments below are common reasons why excavated material is transported.

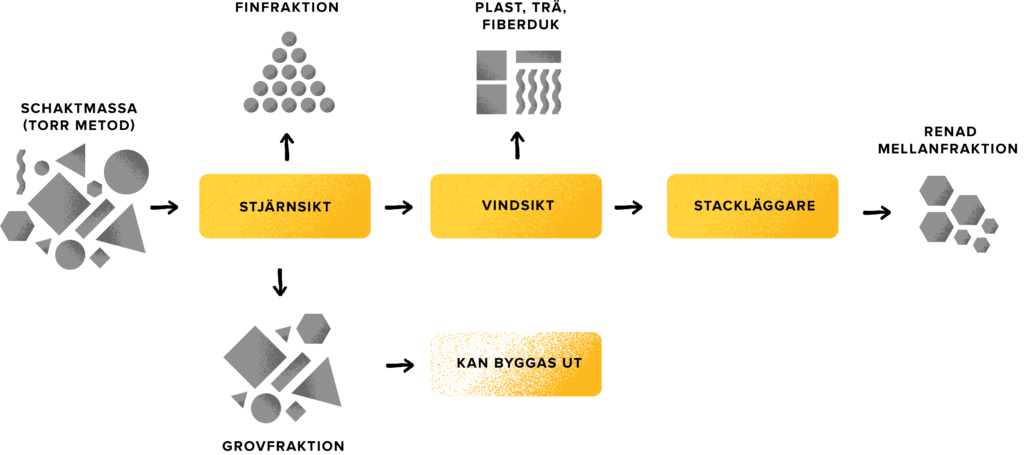

- Loose masses without bearing capacity - Possible solution could be to stabilize loose masses with bentonite or lime in a high capacity Screening plants .

- Mixed soils with high moisture content - Possible solution is to sort by size with star sieves, allowing topsoil to be reused on site or sold.

- Contaminated soils - Possible solution is to sort out the fine fraction that often contains contaminants and blow out organic matter that often absorbs contaminants.

- Stone too large to be used as soil - Possible solution is to divide the stone into several fractions such as macadam, bedding, sand, etc. These fractions can then be used to replace virgin material.

If you want to know how much you can save money and reduce your environmental debt, don't hesitate to contact us to calculate excavation masses and get solutions for your specific project.

What is a carrier layer?

The substrate consists of a mixture of stone and sand. The grain size varies between 0-32 mm, but the greater the proportion of stone, the better the better bearing capacity. Thus, a base layer with a large proportion of stones can carry more than mixtures with smaller stones.

For example, the recycling of subsoil may involve separating impurities from the mass and reducing the size of the stone by crushing.

The major environmental benefit is the avoidance of very heavy transportation and the mining of virgin rock to replace masses already in place.

Recycling of substrates reduces landfill

Efficient recycling of base material and excavated material contributes to better resource management. Often, rock material is transported many miles because there is a lack of knowledge about what is possible with a mobile plant directly on site.

The recycling of excavated material saves the environment and reduces costs. Even if the masses contain environmentally harmful substances, it is often possible to recycle large parts of the mass and thus reduce the use of virgin products, which is a positive environmental aspect.

We have well-developed methods to optimize the recycling of base material and excavated material. We are more than happy to help you find the right machine or concept depending on your local conditions.

In this film, sticky masses are stabilized by adding lime to the screening process.