Vi kan återvinna mycket mer plast

The technology exists to separate more plastic than is currently done. This requires knowledge of what is possible and an active choice to investigate whether the waste can be sorted on site instead of being landfilled or going directly to incineration.

Much unsorted plastic is currently burned by heating plants, sometimes resulting in unnecessary CO2 emissions. Plastic that is not sorted from compost, for example, can also end up back in the environment, which can harm animals and nature.

Norditek ökar återvinningsgraden av plastavfall

Idag energiåtervinns plast som skulle kunna återanvändas eller materialåtervinnas. Här kan vi göra mer. Att man bränner plasten är i vissa fall resurseffektivt men det är inte alltid fallet.

Det viktiga är alltid att man undersöker avfallet som innehåller plast innan man kör det till deponi eller till en avfallspanna. Ofta går det att få ut mer av materialet. Teknikutvecklingen för utsortering av plast går framåt och Norditek har idag flera olika tekniker för att öka förädlingen av avfall som innehåller plast.

Plastic in compost

To tackle the problem of plastics in compost waste, an air extractor or windshifter can be used to separate the plastics. This allows the soil to be reused for soil production and planting instead of being piled up in a landfill. In the process, it is also possible to separate wood and sticks separately, producing a clean biofuel.

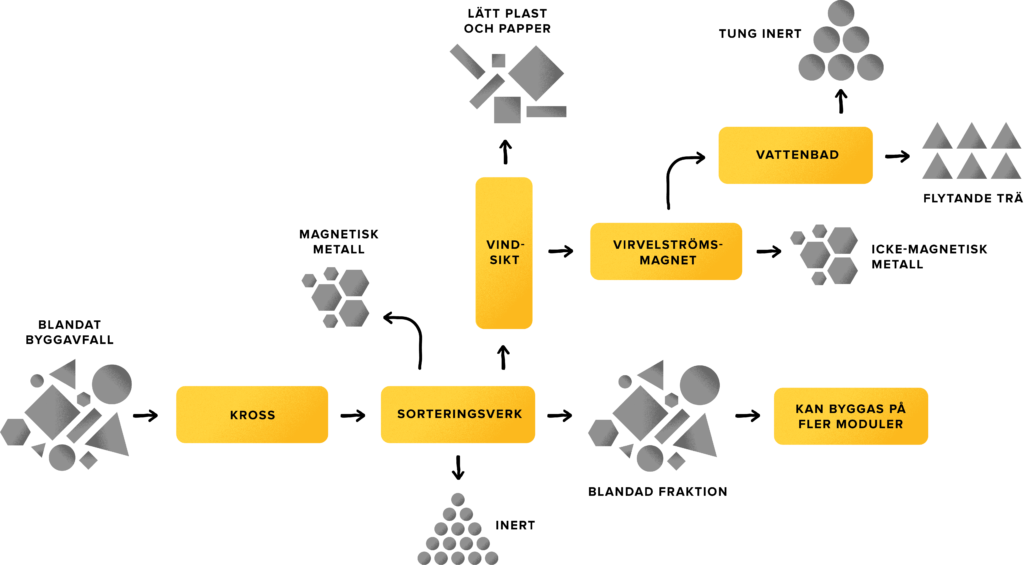

Plastics in construction waste

Plastic contained in unsorted construction waste can now be separated by adding wind and simply blowing away the plastic. This makes it possible to obtain a fossil-free fuel consisting of wood. In such a process, other forces can also be added to separate, for example, metal using magnets.

Plastics in waste sand

The same technology used for plastic in compost can also be used for litter. This means that the sand can be reused again next time instead of going to landfill. This is both more economical and better for the environment.

Purified plastic flows

To the extent that purified plastic streams are obtained, these can in turn be energy recovered by burning waste boilers. This can be a resource-efficient option for plastics that are toxic, contaminated or in some way worn out. Ideally, the plastic can be recycled as a material, but this does not currently apply to all plastics. In the case of material recycling, plastic waste becomes new plastic products.