Recovering gravel from excavated soil

The recycling of excavated soil has significant environmental and economic benefits. Depending on the content, different methods can be used to maximize recycling and transform a waste or fill material into new high quality products.

It is often possible to recycle stone, soil, wood, gravel and metal from excavated materials that do not contain environmentally harmful substances, thus reducing the use of virgin products.

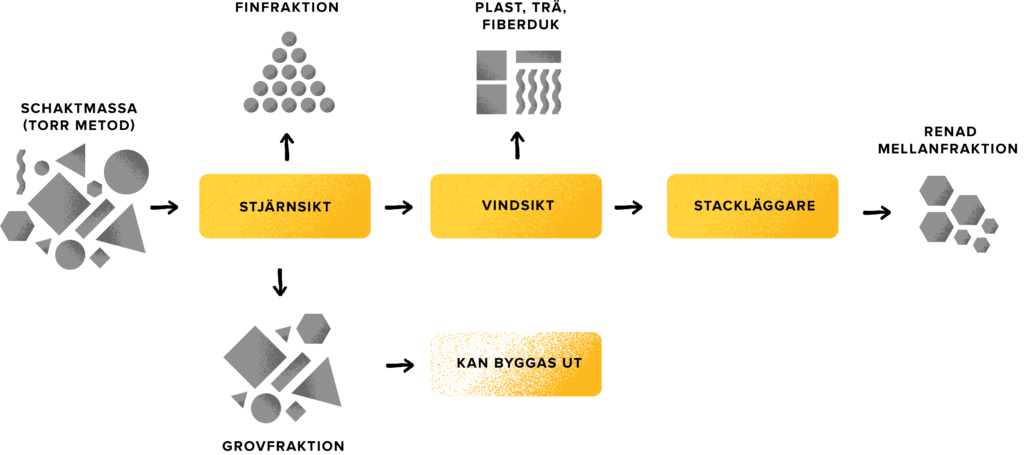

Analys av schaktmassan är avgörande

It is important to analyze the content of the excavated material when choosing a recycling method. If they are contaminated, it is often possible to enrich the contamination so that only a small part needs to be landfilled or destroyed. The analysis is important because some contaminants can lead to damage and pollution in the area.

Contaminated gravel pits

In the past, many operators have found it difficult to recover all the material in a gravel pit, especially the surface layers that are contaminated by the roots of the vegetation overlying the deposit. Particularly in shallow quarries, a lot of material is wasted. In addition, it may also be necessary to separate wood from crushed rock, e.g. crushed from construction rock that has been contaminated with wood or roots.

Many quarry owners have large stocks of material that cannot be delivered for concrete production, but it is possible to screen out unwanted contaminants. Today we can deliver a very well-functioning solution after several years of successful projects in this area.

Gravel recycling with windshifter

Today we have almost 100 windsifters on the Swedish market, largely in the recycling industry. The wind sifter was not originally developed to handle natural gravel, but it turned out after several customers discovered the possibility. This shows the flexibility of our in-house developed products.

The windscreen is capable of blowing away even relatively large materials. When excavating old landfills, materials up to 0.5 meters in size have been easily separated.

With a windshifter it is possible to recycle natural gravel, crushed rock and waste sand in an efficient way.

Recycling of waste sand

The windscreen is also used to blow away other lighter materials such as plastics. Therefore, it can also be used to recycle waste sand. This means that the sand can be reused again next time instead of going to landfill. This is both more economical and better for the environment.

Natural gravel and concrete production

Sticks, roots and other materials found in natural gravel, or for that matter in crushed rock, cause problems for those who want to use the gravel for concrete production and other purposes. In concrete production, for example, this causes problems as the contaminants float up into the finished concrete.