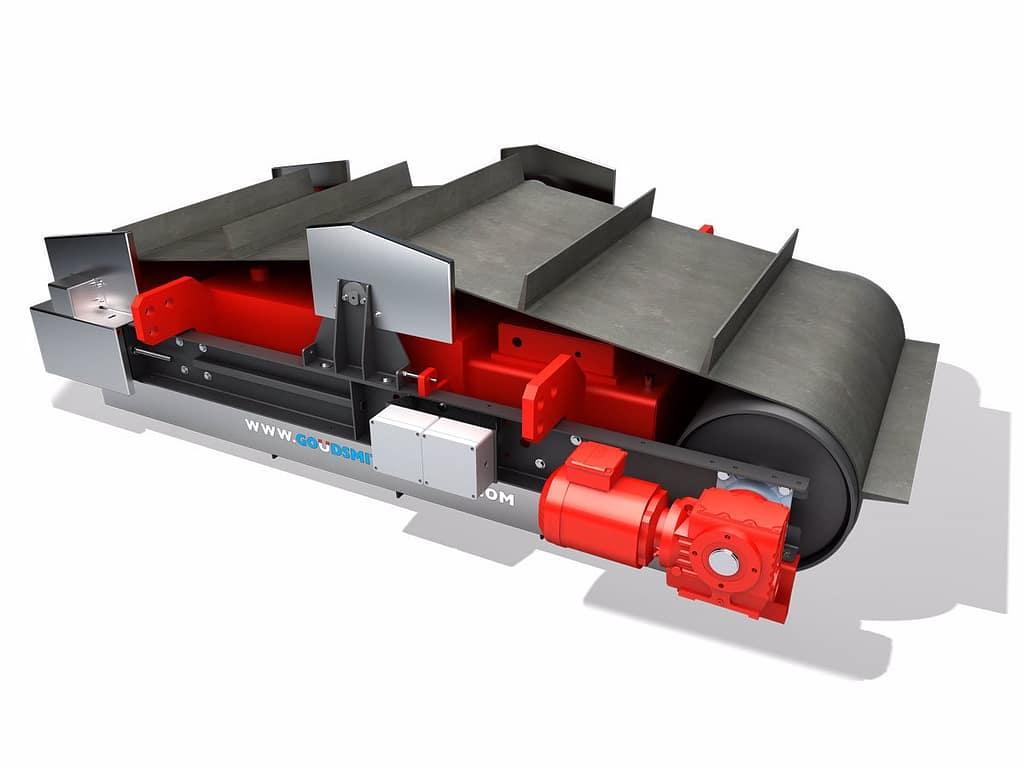

Overband magnet

An overbelt magnet is suitable for separating large volumes of magnetic iron or steel, and is suspended above the belt conveyor. This type of magnet is self-cleaning and continuously separates ferromagnetic parts from material streams. The deferrization efficiency (?) of overband magnets varies from 70 to 90%; depending on the magnet design, product flow and location.

Parts larger than 10 mm

Recovery of iron and elimination of impurities

Fits Norditek's modular system

Product description

Overband magnets with automatic self-cleaning are suitable for both iron recycling and for the removal/elimination of contaminants (iron pollution).

These magnets are mainly suitable for coarse fractions with parts larger than 10 mm. Thanks to the robust and reliable technology, these magnets can be used in many industries. To put a permanent overbelt magnet into operation, nothing more than four suspension points, enough space and a power source to drive the conveyor belt are required.

Document

Feel free to contact us if you have any questions about our products and services.

drift

Speed of the conveyor belt

To remove iron parts from a material flow, they need to remain in a magnetic field for about 0.3 and 0.5 seconds to be magnetized. To achieve maximum separation, it is important to optimize the match between the main pole of the magnet and the speed of the belt.

This means that with a narrow overband magnet, the conveyor belt below it must run at a lower capacity (m/s) than with a wider magnet at the same suspension height. The following formula gives an indication of the maximum speed of the conveyor belt:

Maximum conveyor belt speed (b) = block magnet width (a) / 0.3 (sec)

As an example, this has been calculated for two Goudsmit overband magnets:

Different types of magnets

Overband magnets can be divided into three main types. There are different materials and versions that can serve as a suitable magnet system. Each type has its advantages and disadvantages and therefore its own specific application:

Specification | Ferrites | Neodymium | Electromagnetic |

|---|---|---|---|

Max. mounting height [mm]* | 230 - 450 | 300 - 350 | 360 - 600 |

Magnetic field | Permanent | Permanent | Switchable |

Number of magnet poles in main pole | 3 | 2 | 3 |

Ferro (iron) separation | Yes | Yes | Yes |

Weakly magnetic and stainless steel separation | No | Yes | No |

Compact design | No | Yes | No |

Lightweight | No | Yes | No |

Price | $ | $ | $$ |

*) depending on the selected version; low-budget types have a lower maximum mounting height.

Type: ROP-F1-C

Block magnet width (a): 0.470 m

Results in maximum conveyor belt speed of the material (b): 1.6 m/s

Type: ROP-F3-C

Block magnet width (a): 0.615 m

Results in maximum conveyor belt speed of the material (b): 2.0 m/s

The above formula is a rule of thumb and does not guarantee perfect separation. Longer residence time in the magnetic field always has a positive effect on the degree of separation. If there are long or large ferrous parts in the product flow or if the speed of the conveyor belt cannot be lower than 3 m/s, we recommend a longitudinal magnet.

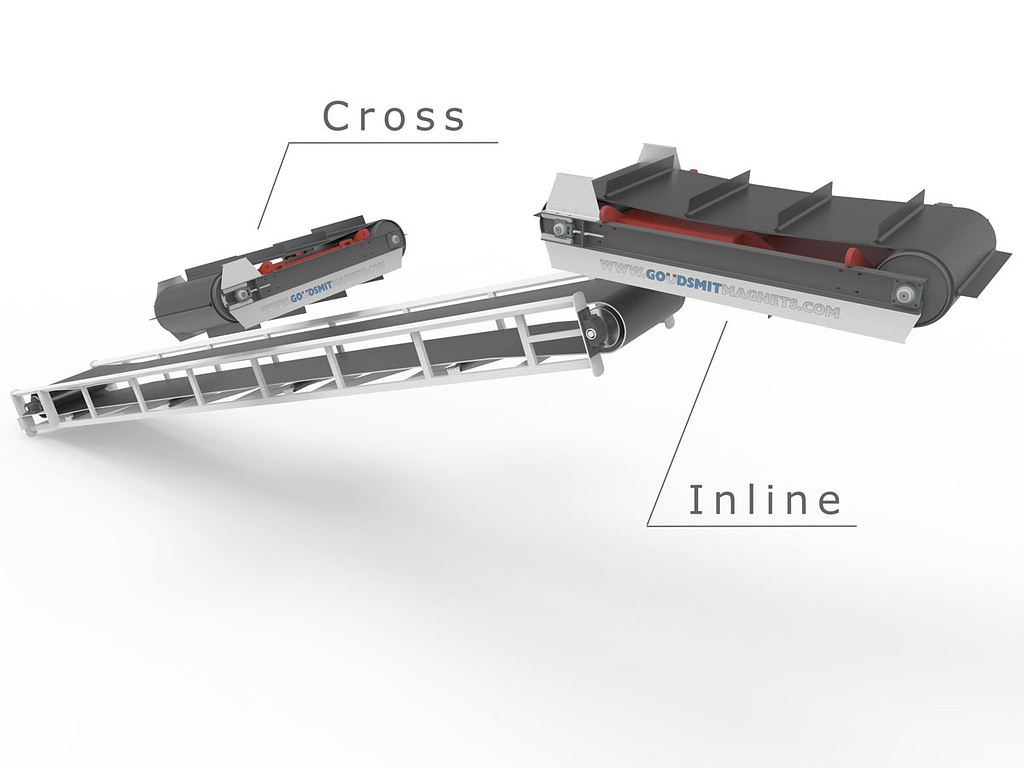

Placement

The distance between a magnet and the conveyor belt must be as small as possible because the magnetic force decreases exponentially with increasing distance. However, a minimum distance is required for carriers to safely remove all the iron parts from the material flow.

There are two methods for using/placing overband magnets: transverse and longitudinal. Goudsmit has a specific, optimized magnet configuration for both mounting options.

Transverse

In practice, transverse placement is most common because it is easier to install in an existing line. An additional advantage is that the iron pieces are fed out to the side, which is easier to process from a logistical perspective.

Longitudinal

If you are able to place your overbelt magnet in line with the conveyor belt, this is always preferable. The advantage of this is that the transported material "breaks up" at the end of the conveyor belt (at the main drum) and thus floats in the air for several milliseconds. As a result, the magnet can easily pull the ferrous metal out of the product flow.

Non-magnetic zone

Note! When placing the magnet, the structure under the magnet - such as the frame, bearing rollers and back rollers - must be made of non-magnetic material. This is because steel parts become magnetized, which will affect the separation performance of the overband magnet. Goudsmit uses the following rule of thumb: keep the area extending a distance of 1/3 of the width of the magnet (shown below as 'a') on all sides free of magnetic material. For the area below the magnet, have a non-magnetic zone that is twice the height of the block magnet ('b'). It is important that all components in this zone are made of stainless steel, plastic or other non-magnetic material.

Longitudinal placement

Transverse placement

Front view

Side view

Products

Ferrite overband magnet

Suitable for thin to thick layers and does not require a control box. Very reliable and available in many bandwidths. Transverse or longitudinal installation above the conveyor belt.

Characteristics

- Powerful, robust and cost-effective

- Max. installation height 450 mm

- Max. layer thickness 300 mm

- Separates iron particles from 1 mm

- For belt widths 400-1 600 mm

- Permanent ferrite magnet

Neodynium overband magnet

Suitable for fine fractions in thin layers and also separates weakly magnetic particles. No control box required. Transverse or longitudinal installation above the conveyor belt. Also for mobile applications.

Characteristics

- Extremely powerful and compact

- Max. installation height 350 mm

- Max. layer thickness 250 mm

- Separates iron and weakly magnetic particles > 1 mm

- For belt widths 700-1 300 mm

- Permanent neodymium magnet

Electromagnetic overband magnet

Electromagnetic overband magnets have a deep penetrating magnetic field and are therefore suitable for very thick layers. A control box is required. Installation perpendicular to or in line with the conveyor belt.

Characteristics

- Deep magnetic field

- Max. installation height 600 mm

- Max. layer thickness 450 mm

- Separates iron particles from 1 mm

- For belt widths 800-1 600 mm

- Electromagnet (oil-cooled)