End roller magnet

The end roller magnet separates strongly magnetic particles such as iron or steel and weakly magnetic particles such as processed stainless steel. The separation is done from coarse to very fine fractions and is fully automatic.

The magnetic roller is built into an existing conveyor belt system and is a cost-effective magnetic metal separator.

From coarse to fine fractions

Separates magnetic particles

Fits Norditek's modular system

Document

Feel free to contact us if you have any questions about our products and services.

Usage

The end roller magnet is particularly well suited for the separation of complex shapes such as ball bearings or batteries and is used for the recycling of ferrous metals.

The magnetic roller requires virtually no maintenance. As the magnets are integrated, there are no additional operating and energy costs.

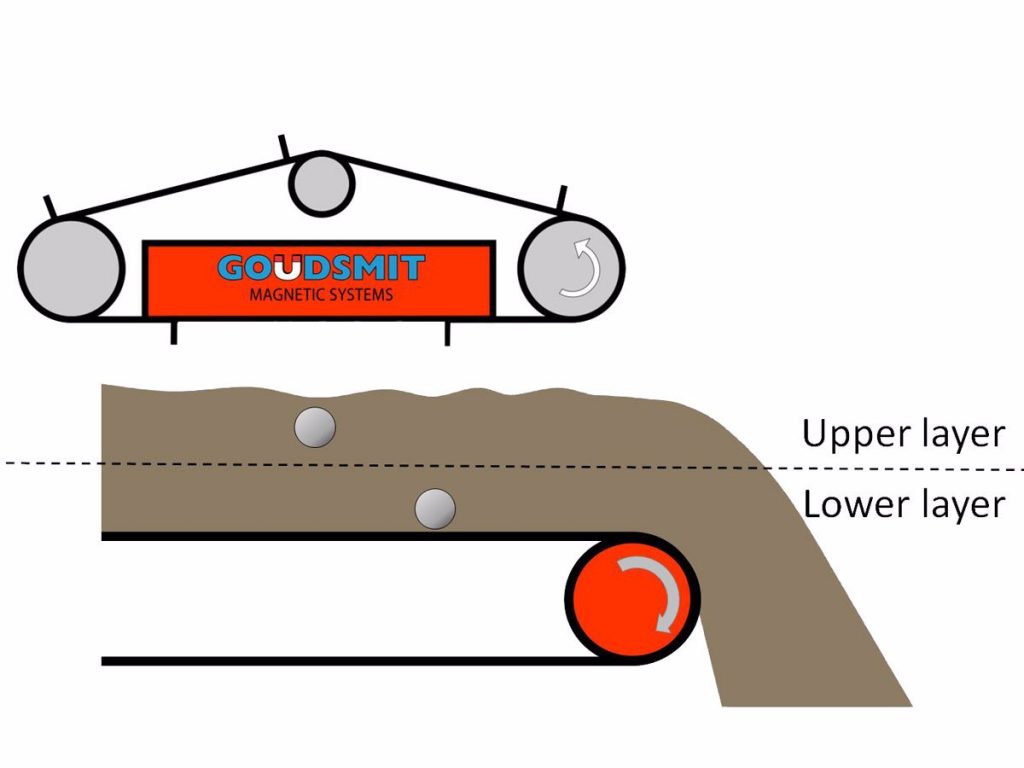

For larger layer thicknesses, an end roller magnet can be combined with, for example, an overband magnet. In this configuration, the overband magnet pulls the steel pieces from the upper layer and the end roller magnet pulls them from the lower layers of the material flow.

For strongly magnetic particles, we can place "carriers" that push the particles out of the magnetic field. For moist or fine metal particles, we mount a scraper to prevent them from sticking to the belt.

Note that it is important to feed the material on the conveyor belt with the magnetic roller in a thin layer.

The magnetic field is active around the entire circumference and attracts ferromagnetic particles from a material flow. The conveyor belt running over the roller carries these particles to the underside of the roller. When they are no longer within the range of the magnetic field, they fall off the belt to be collected and/or carried away.

Because the material passes very close to the magnet, it acts as a very powerful and efficient separator.

Products

Optional end roller magnet

The product is installed in existing belt conveyors.

Characteristics

- Separates Fe and weakly magnetic particles > 0.5 mm

- Automatic separation

- Max. layer thickness 100 mm

- Max. product size 100 mm

- For belt width 400 - 2000 mm

- With ferrite or neodymium magnets

End roller magnet integrated in system

The system is used to capture weakly magnetic particles. Due to the low magnetic field depth, this system is not suitable for high processing capacity.

Characteristics

- Separates Fe and weakly magnetic particles > 0.1 mm

- Automatic separation

- Max. layer thickness 30 mm

- Max. product size 50 mm

- For belt width 600 - 800 mm

- Neodymium magnets