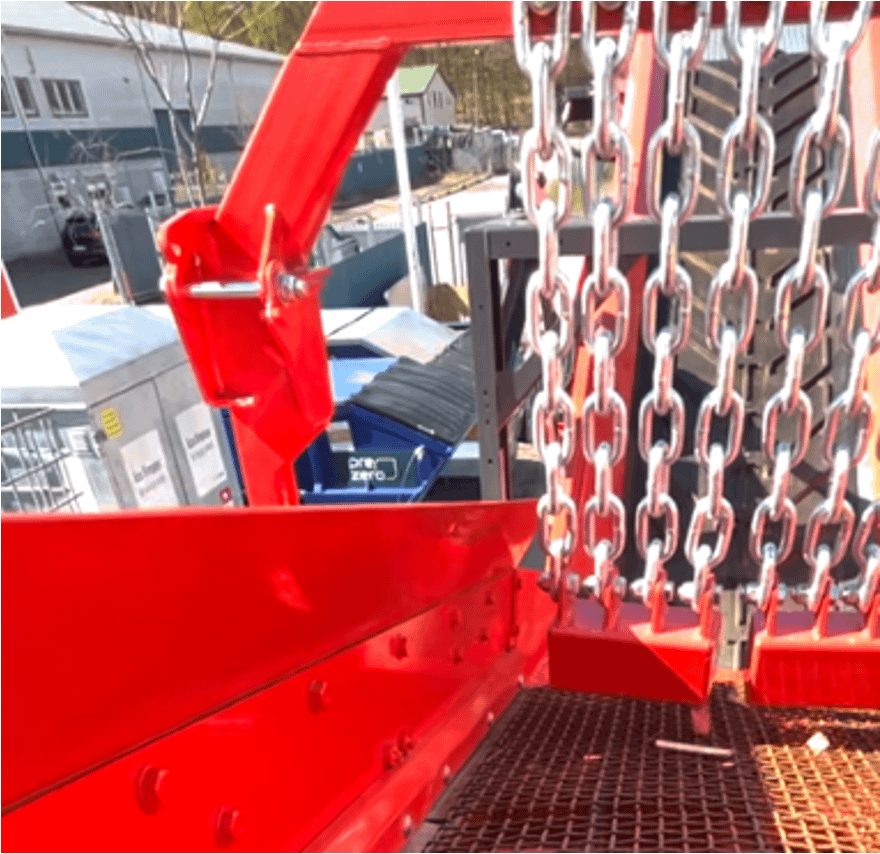

- reduces conveyor wear and tear on oversize fraction

- better sorting of coarse materials

| Machine model | Finlay 883+, Norditek ES5200 |

|---|---|

| Type of material | For heavier materials |

| Sighting box | Mountain box |

- covers 100 % of the overhead conveyor

- important for future use of the overband magnet

- reduces wear and tear on the over-fraction conveyor

- suitable for stumps

- smaller stone fraction

- For soils and wood waste

- Available in PUR (polyurethane) for sticky materials

- Available in rubber for dry materials

- Capable of high capacity

- Different sizes and number of fingers depending on the material

- Original spare parts from Backers

- Please note that different materials are handled with different dimensions

- important when using an overband magnet

- the brush keeps the lamella feeder clean in damp and muddy conditions

- Provides stair-step effect

- Turns the material

- Maximizes extraction of fine material

- stainless steel plates on fine and intermediate conveyors

- for the collection of magnetic scrap

Feel free to contact us and we will tell you more about how you can maximize your recycling.