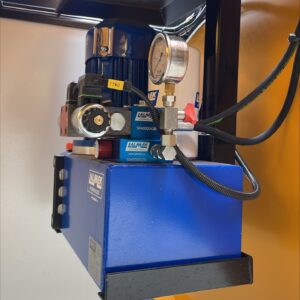

Oil heater. Electric

- engine and hydraulic oil heaters

- electric drive

| Machine model | Tana Shark 440 |

|---|

Suitable for Tana's slow-speed crusher but can also be adapted to other waste crushers. Please contact us if you have any questions.

More spare parts

-

Electric outriggers

- hydraulic

-

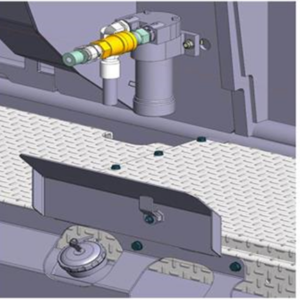

Actuator upgrade kit

-hydraulic actuators for gap adjustment windshifter

-reliable and strong construction for trouble-free production -

Output belt

- is used instead of the discharge chute

- for greater stack height on the light fraction -

Footbridge brackets

- secures the ladder during inspection

- improves the working environment -

Hand nozzle

- hand nozzle for hose

-

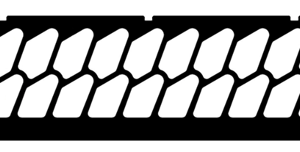

Stone band

- Standard stone tape for windshifter

- For materials below 100 mm

- Possible to add end roll magnet -

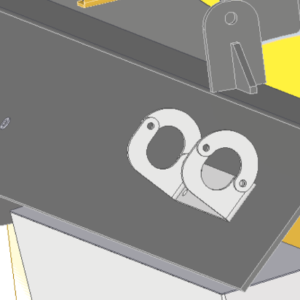

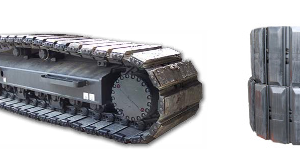

Rubber-coated caterpillar feet

- reduces damage to the substrate

- for steel caterpillar tracks -

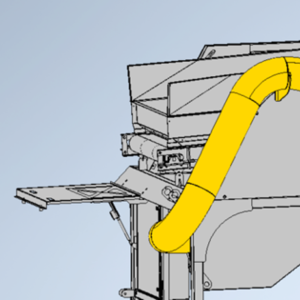

Snorkel

- avoids clogging of air intakes

- used for lightweight materials -

Stars wear parts

- For soils and wood waste

- Available in PUR (polyurethane) for sticky materials

- Available in rubber for dry materials

- Capable of high capacity

- Different sizes and number of fingers depending on the material

- Original spare parts from Backers

- Please note that different materials are handled with different dimensions -

Belt conveyor

-Galvanized, electrically powered conveyors

-Ideal for high flows and volumes

-Available in belt widths from 450 to 1500 mm

-1200 mm used for light fraction windshifter

600/900 mm used for heavy fraction windshifter -

Fingers waste box

- Provides stair-step effect

- Turns the material

- Maximizes extraction of fine material -

Filling pump electric

- simplifies refuelling

-

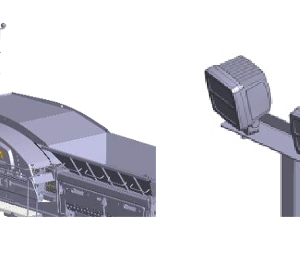

Light pole

- for a better and safer working environment in the dark

- 2 x 50W LED -

Fire extinguishers

- easily accessible for quick extinguishing

- powder extinguishers

- 2x6kg -

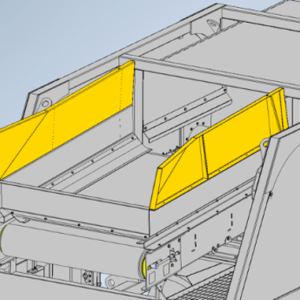

Guide plates

- plates to guide light material down to the accelerator

- reduces contamination

- improves the working environment on the walkway -

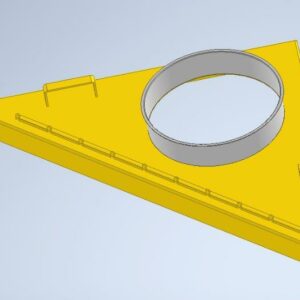

Plough

- is used for better dispersion of the material

- provides more efficient separation -

Scraper

- clears the accelerator of material

- provides better sorting

- reduces the need for cleaning -

Suction nozzle XL

-adapted with brackets for intermediate fraction belts on Norditek flipflow screen

-

Dust control systems

- improves the working environment

- water mist binds the dust particles -

Container adapter

- adapter keeps hose in place in the container

-

Oil heaters. Diesel fuel

- engine and hydraulic oil heaters

- diesel operation -

Stainless steel sheets

- stainless steel plates on fine and intermediate conveyors

- for the collection of magnetic scrap -

Holder for more sieve baskets

- holder for more sieve baskets on the machine

-

Roof hydraulics

- reduces injury risk and cleaning needs

- protects the hydraulic system -

Power cable/starter cable

-

HD Rotor

- crushes high-wear materials

- minimizes maintenance time and significantly increases operating hours -

Remote control

- on & off machine

- change rotor direction

- give sound signal

- open rotor door

- running the machine in caterpillar mode only -

Sieve plate for crushing tires

- sieve plate optimal for crushing tires

-

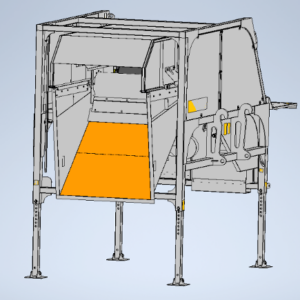

Feeding outfeed hopper

- PU plate for reduced wear

- avoids adhesion of sticky materials

- suitable for sound-sensitive environments thanks to reduced noise level -

Suction nozzle

- adapted with brackets for intermediate fraction belts on Norditek flipflow screen

-

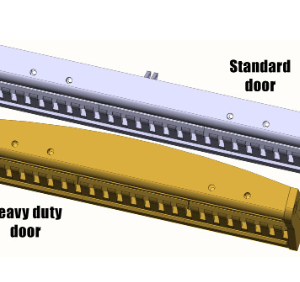

HD door

- hardox lined for less welding time and more run time

- for tough applications -

Rubber stopper

- for the collection of materials

- used with a conveyor