Rubber stopper

- for the collection of materials

- used with a conveyor

| Machine model | Norditek windshifter |

|---|

Suitable for the Norditek VS1200 series. Please contact us if you have any questions.

More spare parts

-

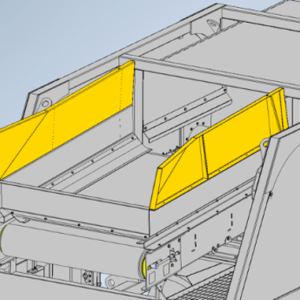

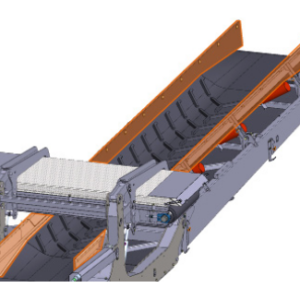

Guide plates

- plates to guide light material down to the accelerator

- reduces contamination

- improves the working environment on the walkway -

Dust control systems

- improves the working environment

- water mist binds the dust particles -

Fire extinguishers

- easily accessible for quick extinguishing

- powder extinguishers

- 2x6kg -

Cutting plate for roller

- automatically clears material around the distribution roller

- e.g. from VHS cassettes and cords

- avoids stock-outs/breakdowns -

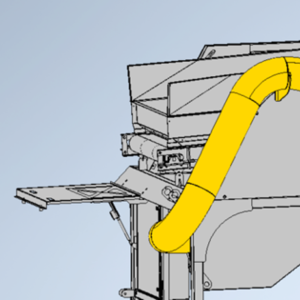

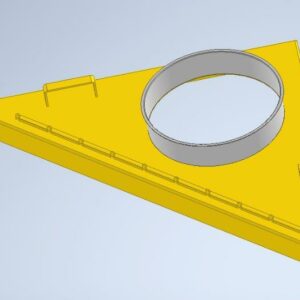

Snorkel

- avoids clogging of air intakes

- used for lightweight materials -

First aid kit

-

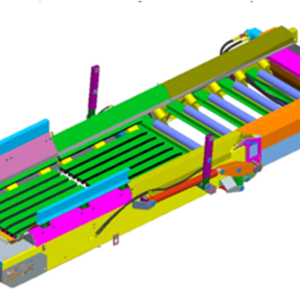

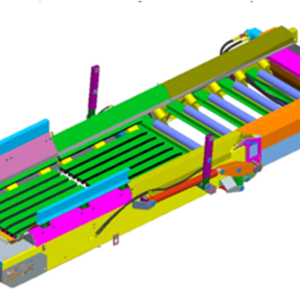

Discharge plunge

- option for output conveyor

- collects the material

- for larger fractions -

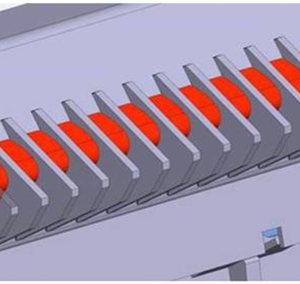

Fingers waste box

- Provides stair-step effect

- Turns the material

- Maximizes extraction of fine material -

Non-magnetic damping pads

- important when using an overband magnet

-

Electric outriggers

- hydraulic

-

Container adapter

- adapter keeps hose in place in the container

-

HD reindeer shame

- reinforced reindeer hide

- for tough applications -

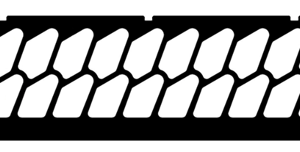

Stone band

- Standard stone tape for windshifter

- For materials below 100 mm

- Possible to add end roll magnet -

Brush under feeder

- the brush keeps the lamella feeder clean in damp and muddy conditions

-

Scraper

- clears the accelerator of material

- provides better sorting

- reduces the need for cleaning -

Stone brake for lighter materials

- reduces wear and tear on the over-fraction conveyor

- suitable for stumps

- smaller stone fraction -

Actuator upgrade kit

-hydraulic actuators for gap adjustment windshifter

-reliable and strong construction for trouble-free production -

HD Rotor

- crushes high-wear materials

- minimizes maintenance time and significantly increases operating hours -

Oil heaters. Diesel fuel

- engine and hydraulic oil heaters

- diesel operation -

Suction nozzle

- adapted with brackets for intermediate fraction belts on Norditek flipflow screen

-

Stars wear parts

- For soils and wood waste

- Available in PUR (polyurethane) for sticky materials

- Available in rubber for dry materials

- Capable of high capacity

- Different sizes and number of fingers depending on the material

- Original spare parts from Backers

- Please note that different materials are handled with different dimensions -

Holder for more sieve baskets

- holder for more sieve baskets on the machine

-

HD stone brake

- reduces conveyor wear and tear on oversize fraction

- better sorting of coarse materials -

Non-magnetic damping plates

- covers 100 % of the overhead conveyor

- important for future use of the overband magnet -

Hand nozzle

- hand nozzle for hose

-

Side protection

- prevents light material from blowing off the conveyor belt

- for light materials e.g. plastic -

Stainless steel sheets

- stainless steel plates on fine and intermediate conveyors

- for the collection of magnetic scrap -

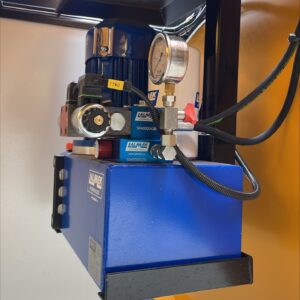

Roof hydraulics

- reduces injury risk and cleaning needs

- protects the hydraulic system -

HD Output belt

- heavy fraction discharge conveyor

- with reinforced chassis and dam plates

- larger drive and turning rollers

- thicker and cut-resistant mat -

Sieve plate for crushing tires

- sieve plate optimal for crushing tires

-

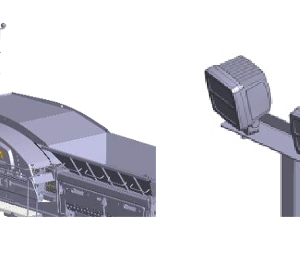

Light pole

- for a better and safer working environment in the dark

- 2 x 50W LED -

Remote control

- on & off machine

- change rotor direction

- give sound signal

- open rotor door

- running the machine in caterpillar mode only