- more powerful air nozzle

- to maintain airflow through deformation

- needed for heavy fractions

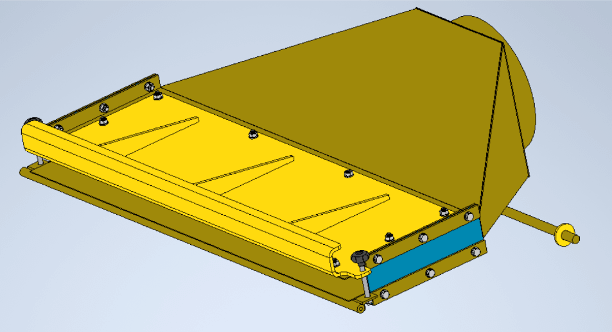

| Machine model | Norditek wind shifter |

|---|---|

| Type of material | For heavier materials |

Suitable for the Norditek VS1200 series. Please contact us if you have any questions.

- option for output conveyor

- collects the material

- for larger fractions

- is used for better dispersion of the material

- provides more efficient separation

- for the collection of materials

- used with a conveyor

- avoids clogging of air intakes

- used for lightweight materials

- reduces injury risk and cleaning needs

- protects the hydraulic system

- clears the accelerator of material

- provides better sorting

- reduces the need for cleaning

- is used instead of the discharge chute

- for greater stack height on the light fraction

- on & off machine

- change rotor direction

- give sound signal

- open rotor door

- running the machine in caterpillar mode only

- heavy fraction discharge conveyor

- with reinforced chassis and dam plates

- larger drive and turning rollers

- thicker and cut-resistant mat

- secures the ladder during inspection

- improves the working environment

- plates to guide light material down to the accelerator

- reduces contamination

- improves the working environment on the walkway

- automatically clears material around the distribution roller

- e.g. from VHS cassettes and cords

- avoids stock-outs/breakdowns

Feel free to contact us and we will tell you more about how you can maximize your recycling.