Loose masses without bearing capacity

- Problem: Loose spoil can lack stability and load-bearing capacity, making it difficult to use directly in construction projects.

- Solution: Possible solution could be to stabilize loose masses with bentonite or lime in a high capacity Screening plants .

Mixed soils with high moisture content

- Problem: Excavated material with high moisture content can be difficult to handle and reuse directly.

- Solution: Possible solution is to sort by size with star sieves allowing topsoil to be reused on site or sold.

Contaminated soils

- Problem: Contaminated soils can spread harmful substances and require special treatment.

- Solution: Possible solution is to sort out fine fraction where often pollutants are located and blow out organic which often absorbs pollutants.

Too much large stone to be used as soil

- Problem: Large stones cannot be used directly as soil and require further processing.

- Solution: A possible solution is to divide the stone into several fractions, such as macadam, carrier layer, sand, etc. These fractions can then be used to replace virgin material.

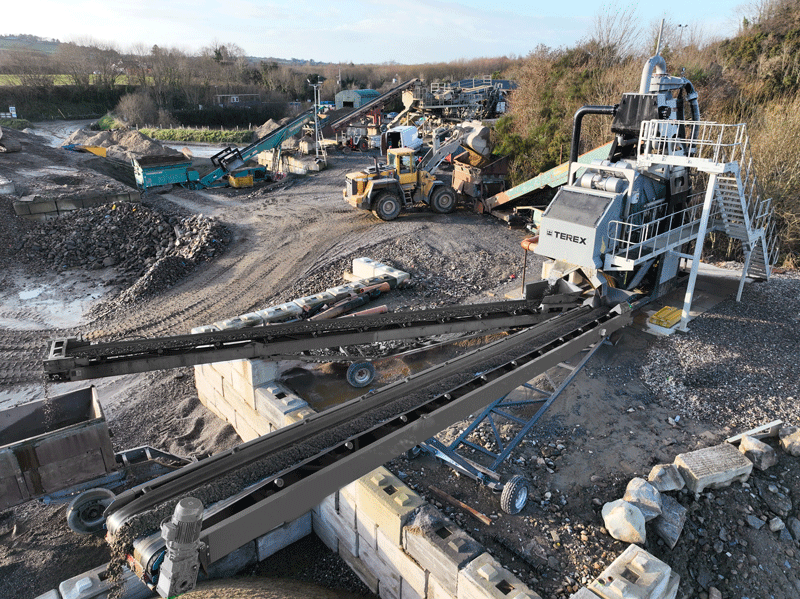

The right technology to recycle excavated material

- Mobile laundry facilities

- Wind sifting

- Density separation

- Reuse of aggregates

Recycling of excavated material for sustainable resource management

Efficient management and recycling of excavated material is crucial for sustainable resource management. By implementing advanced technologies and solutions, we can reduce the amount of waste sent to landfill, conserve natural resources and protect the environment for future generations. Norditek offers a wide range of methods and equipment to meet these challenges in a cost-effective and environmentally friendly way .

For more information on how to optimize the management of excavated material in your project, contact us